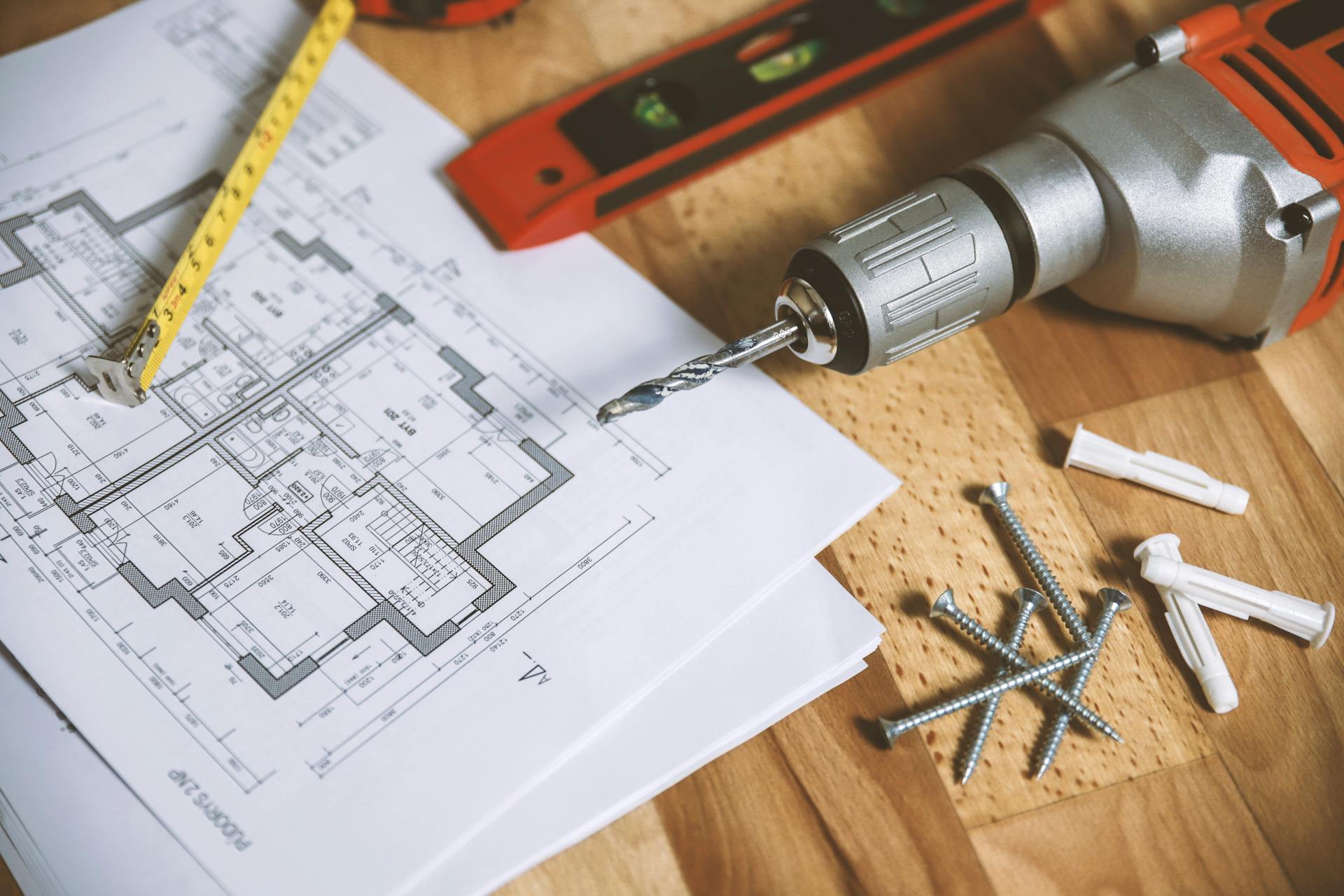

Dtf transfers are a type of image transfer that allows you to print your own designs onto t-shirts, fabric, wood, and other materials. The process is simple and easy to do at home with just a few supplies.

To get started, you'll need the following supplies:

-A printer that can print onto transfer paper

-Dtf transfer paper

-A cutting tool like scissors or a craft knife

-A heat source like an iron or a heat press

-A piece of cardboard or something similar to protect your work surface

-A piece of cloth or t-shirt to transfer your design onto

First, you'll need to create your design. This can be done in a number of ways, but the easiest is to find an image online or in a design program like Photoshop and resize it to fit your transfer paper. Once your design is ready, print it out onto the transfer paper following the manufacturer's instructions.

Next, use your cutting tool to cut out your design from the transfer paper. Be sure to leave a small border around the edge of your design.

Now it's time to transfer your design onto your chosen surface. Place your design face-down on your surface and position it where you want it. Cover the design with a piece of parchment paper or a thin cloth and apply firm pressure with your heat source. Slowly move the heat source back and forth over the design for about 30 seconds to 1 minute.

Allow the design to cool for a few minutes before carefully peeling back the transfer paper. If any parts of your design have not transferred, simply reapply the heat and press again.

And that's it! You've now successfully transferred your design onto your surface using dtf transfers.

Recommended read: Make Full Color Screen Print Transfers

What type of printer do I need to print dtf transfers?

If you're looking to print dtf (direct-to-garment) transfers, you'll need a specialized printer that is capable of handling the medium. While there are a few different types of dtf printers on the market, the two most popular are inkjet and laser.

Inkjet printers are typically the more affordable option and are perfect for those who don't plan on doing a lot of printing. Laser printers, on the other hand, are more expensive but offer a higher quality print. If you plan on doing a lot of dtf printing, a laser printer may be the better option for you.

When it comes to choosing the right dtf printer, there are a few things you'll need to keep in mind. First, consider the types of garments you'll be printing on. If you only plan on printing on light-colored fabrics, an inkjet printer should be fine. However, if you want to be able to print on dark-colored fabrics, you'll need a laser printer.

Second, think about the size of the prints you'll be making. If you only need to print small designs, an inkjet printer will be sufficient. But if you plan on printing large designs, you'll need a laser printer.

Finally, consider your budget. Inkjet printers are typically more affordable than laser printers, so if you're on a tight budget, an inkjet printer may be the better option for you. However, if you can afford it, a laser printer will offer you the best quality prints.

No matter which type of printer you choose, make sure you do your research to find the one that best suits your needs. With a little bit of effort, you'll be able to find the perfect printer for printing dtf transfers.

Here's an interesting read: Inkjet Prints

What type of paper do I need to use?

There are many types of paper available on the market today and choosing the right one can be confusing. Here is a guide to help you choose the right type of paper for your project.

The first thing you need to determine is what the paper will be used for. There are different types of paper designed for different purposes. For example, there is copy paper, which is designed for printing documents; card stock, which is thicker and more durable and is often used for making cards and invitations; and photo paper, which is specially coated to produce high-quality photos.

Once you know what the paper will be used for, you need to consider what kind of look you want to achieve. For example, do you want a glossy or matte finish? What about texture? There are many different types of paper with different finishes and textures available, so you can find one that suits your project perfectly.

Finally, you need to think about the size of the paper. Paper comes in a range of sizes, from small notebook paper to large poster board. You need to make sure you choose a size that is appropriate for your project.

Now that you know all of this, you are ready to choose the right type of paper for your next project!

Curious to learn more? Check out: Construction Paper

How do I set up my printer to print dtf transfers?

If you want to print dtf transfers, there are a few things you need to do first. To start, you'll need a printer that is compatible with dtf transfer paper. Not all printers are, so be sure to check before you buy. Once you have a compatible printer, you'll need to purchase dtf transfer paper. This can be found at most office supply stores.

Now that you have your printer and paper, you're ready to print! Begin by word processing the design you want to print. When you're happy with it, hit print. But before you do, make sure to change your printer settings. Dtf transfer paper is sensitive to heat, so you'll need to adjust your printer's settings accordingly. We recommend printing on the lowest heat setting possible.

Once your print job is complete, let the paper cool for a few minutes before you attempt to remove it from the printer. If you try to remove it while it's still warm, you risk damaging the dtf transfer. When the paper is cool, gently peel it away from the printer. If your design has printed correctly, it will now be transferred to the dtf paper. If it hasn't, you can try reprinting on a higher heat setting or using a different type of paper.

Discover more: Remove Print

What is the best way to print dtf transfers?

Dtf transfers are a great way to print your photos, but they can be tricky to get right. Here are a few tips to help you get the best possible results:

1. Make sure your printer is properly calibrated. This will ensure that your colors are accurate and that your prints are consistent.

2. Use high quality paper. This will prevent your photos from looking fuzzy or pixilated.

3. Use a high quality inkjet printer. This will produce the best quality prints.

4. Follow the instructions that come with your transfer paper. This will help you avoid any problems.

5. Test your printer settings before you print your final product. This will ensure that you are happy with the results.

6. Be patient. Dtf transfers can take a little longer to print than regular photos, so be prepared to wait a few extra minutes.

7. Don't be afraid to experiment. Dtf transfers offer a lot of flexibility, so feel free to try different settings and papers to see what works best for you.

Check this out: Store Screen Print Transfers

How do I ensure that my dtf transfers come out correctly?

There are a few key things to keep in mind when sending or receiving dtf transfers. First, both sender and receiver should be using the latest version of the dtf client. Second, the sender should always initiate the transfer, and the receiver should always confirm the transfer. Finally, both sender and receiver should have their respective dtf accounts properly configured.

Assuming both sender and receiver have met the above requirements, the sender should first log into their dtf account and navigate to the 'Send Money' page. Here, the sender will need to enter the recipient's dtf account number, the amount to be transferred, and a description of the transaction. Once all the necessary information has been entered, the sender should click the 'Submit' button to initiate the transfer.

The receiver will then receive a notification of the pending transaction. At this point, the receiver should log into their dtf account and navigate to the 'Transactions' page. Here, the receiver will see the pending transaction and will have the option to either accept or reject it. If the receiver chooses to accept the transaction, they will simply need to click the 'Confirm' button. Once the transaction has been confirmed, the funds will be transferred from the sender's account to the receiver's account and both parties will receive an email notification confirming the successful transfer.

What are some common problems that can occur when printing dtf transfers?

There are a few common problems that can occur when printing dtf transfers. The most common problem is that the transfer can become wrinkled or creased, which can cause the design to become distorted. Another common problem is that the transfer can peel away from the paper, which can cause gaps or missing parts of the design. Finally, the colors of the design can sometimes bleed or run together, which can ruin the look of the transfer.

How can I troubleshoot printing problems with dtf transfers?

One of the most common issues people have when printing dtf transfers is that the colors don't seem to be very true to what they see on their computer screen. This can be frustrating, especially if you've spent a lot of time creating a design only to have it not look quite right when you print it. Luckily, there are a few things you can do to troubleshoot this issue.

The first thing you'll want to do is check your settings. Make sure you're using the correct color mode for your printer. If you're not sure, consult your printer's manual or look online for the specific model. For most inkjet printers, you'll want to use the CMYK color mode.

Once you've checked your settings, take a look at your design. Are there any areas where the colors are very saturated or dark? If so, you may want to adjust your design accordingly. Remember that printing on dtf transfers can sometimes result in colors looking a bit lighter than they do on your screen.

If you're still having trouble getting your colors to look right, there are a few other things you can try. One is to print a test page on plain paper first. This will help you see if the colors are printing correctly. If they're not, you can adjust your settings or design accordingly.

Another option is to use a color management system. This software will help to ensure that the colors in your design are printed accurately. This is a good option if you're having trouble with multiple colors in your design.

If you've tried all of these things and you're still having trouble printing dtf transfers, you may need to contact a professional printing company. They can help you troubleshoot your specific issue and get your design printed correctly.

For another approach, see: Printed Document

What are some tips for getting the best results when printing dtf transfers?

There are a few factors to consider when printing dtf transfers to ensure the best results. The first is the quality of the transfer paper. There are a variety of transfer papers on the market, and it is important to select one that is compatible with the type of printer being used. For example, some transfer papers are only compatible with inkjet printers, while others can be used with both inkjet and laser printers.

It is also important to use the correct settings on the printer. The transfer paper should be loaded into the printer according to the manufacturer's instructions. For best results, it is often recommended to use the highest quality setting on the printer. This will ensure that the image is printed at the highest possible resolution.

Once the transfer paper is loaded into the printer, the next step is to print the image. It is important to make sure that the image is printed on the correct side of the paper. The transfer paper typically has a glossy side and a matte side. The glossy side is the side that should be printed on.

After the image is printed, it is time to apply the transfer. The transfer paper should be trimmed to the same size as the image. It is important to use a Teflon sheet or some other type of non-stick surface to protect the printer bed. The transfer should be placed on the surface with the glossy side facing up.

A heat press machine is then used to apply the transfer to the garment. The transfer paper should be placed on the garment with the glossy side down. The heat press machine is then set to the proper temperature and time. The transfer will be permanently adhered to the garment after the specified time has elapsed.

It is important to allow the garment to cool completely before removing the transfer paper. If the transfer is removed while the garment is still warm, it is likely to peel off. Once the garment has cooled, the transfer can be carefully peeled off.

These are just a few tips for getting the best results when printing dtf transfers. By following these tips, you can ensure that your transfers will look great and last for a long time.

For your interest: Curved Surface

How can I make sure my dtf transfers last?

There are a few things you can do to prevent your dtf transfers from fading. Here are a few tips:

1. Use a high quality dtf transfer paper. This will ensure that your transfer is sharp and vibrant.

2. Follow the directions on the dtf transfer paper package. This will help you avoid any mistakes that could cause your transfer to fade.

3. Make sure the fabric you are transferring your design to is clean and free of any oils or residue. This will help your transfer adhere better and last longer.

4. Use a hot iron when applying your transfer. This will help set the design and prevent it from fading.

5. Avoid washing the fabric with your design on it in hot water. This can cause your transfer to fade.

6. Store your fabric with your design in a cool, dark place. This will help prevent your transfer from fading.

7. Follow these tips and your dtf transfer should last for a long time!

A different take: Foil Print Fabric

Frequently Asked Questions

How do I make a DTF print with PET film?

Just like any other print, you’ll need to set up your printer and make sure the PET film is loaded in the trays. Then hit the print button! Remember to be careful not to smudge the print when you remove it from the tray.

What is the difference between DTG and DTF printing?

DTG printing is a process that uses an inkjet printer to print on demand. DTF printing is a more advanced process that uses a specific type of water-based ink and film transfer.

What is DTF printer ink used for?

DFT printer ink is specifically designed for use with the DTF process. DFT removes linings that occur on white layer prints caused by the traditional print-making process, which rectifies their appearance.

What do I need to start a DTF printing business?

To start a DTF printing business, you will need a DTF printers and contact printer hardware. The software required is RIP (registered interactive pricing) and Hot Melt Adhesive Powders. The cost of the materials varies so please see below for more details: What are the costs of starting a DTF Printing Business? The initial outlay for starting a DTF printing business is around £3,000 - £5,000. This price includes the cost of a DTF printers, PET coated transfer films and required software.

What are DTF transfers?

DFT transfers are digital toner heat transfers that give you the advantage to print on any color tshirts and any material including: Cotton, poly, denim, silk & more. When heat pressed to the garment, the designs are soft, stretchy, vibrant, durable and long lasting. DFT transfers can be used for apparel printing, vehicle graphics, pet graphics and much more.

Sources

- https://yeson30.org/about/

- https://www.arduinolibraries.info/libraries

- https://www.pcgamer.com/overwatch-2-reaches-25-million-players-tripling-overwatch-1-daily-peaks/

- https://www.ppic.org/publication/ppic-statewide-survey-californians-and-their-government-october-2022/

- https://www.protocol.com/newsletters/entertainment/call-of-duty-microsoft-sony

Featured Images: pexels.com