Sublimation printing, or dye sublimation, is an increasingly popular printing process with a special set of tools, materials, and software. It’s used to create everything from custom apparel and household items to signs and displays. To get the most out of the process, it’s important to use the right program when you’re creating your designs.

One great way to start diving into sublimation printing is with CorelDRAW. This program gives designers a lot of creative freedom when designing their digital art. Beginners and experts alike can create intricate designs quickly with its wide range of drawing tools, pencils, and brushes. Plus, you’ll be able to export your files directly for use in sublimation printing.

Adobe Photoshop is a great go-to for painting projects and customized graphics for sublimation printing designs. The full library of filters provides limitless opportunities for creating eye-catching visuals that won’t take long to edit either. You can import images straight into the canvas or draw out your own designs before exporting them as ready-to-print files compatible with any type of thermal transfer printer.

Finally, Adobe Illustrator is a must-have for those who want to create stunning vector art for their custom sublimation print projects. By using its grid feature, you can quickly craft elaborate patterns in any size or shape you need—saving time compared to drawing and coloring each element individually by hand. With every part nicely aligned and neatly organized into layers, it’s easy to prepare final files that look perfect when printed on all kinds of fabrics or materials where small details are essential..

In conclusion, each program has its strengths when preparing files for sublimation prints. No matter what level of experience you have designing digital graphics, CorelDRAW, Adobe Photoshop and Adobe Illustrator are all powerful tools that will help you produce bold prints with beautiful colors that stand out from the crowd.

Consider reading: Bright Sublimation Prints

What software is best for creating sublimation designs?

Creating stunning designs to be used with sublimation printing is a rewarding, yet challenging task. With the right tools and software, it’s easy to create stunning sublimation designs for everything from t-shirts and mugs to fabric and posters. When selecting the right software for creating sublimation designs, it's important to select something that provides the features you need and fits your budget.

For those who are first starting out, Adobe Photoshop is usually a great place to begin. As one of the most comprehensive graphic design programs available on the market, Photoshop offers simple tools for creating and editing photos while also providing more detailed design capabilities if needed. Additionally, its Creative Cloud subscription can be purchased monthly or annually depending on your needs.

For those in need of something more specialized for sublimation design specifically, there is Sure Colour Subli Suite V2 by Grace Engineered Products. SCSSV2 has become a leading choice amongst designers thanks to its array of options including templates, Pantone Spot Color Swatches, Professional RGB Workflows & ICC Profiles; all while being affordable with no subscription fees needed! The suite also includes vector design tools such as Inkscape and Illustrator - giving users flexible photoscaping capabilities as well as direct export into popular formats.

At the end of the day whichever software tool you choose should depend on your budget and desired end product - but with options like Adobe Photoshop and Subli Suite V2 readily available there’s sure to be something that will meet your exact needs!

Here's an interesting read: Computer Aided Design Program Cad

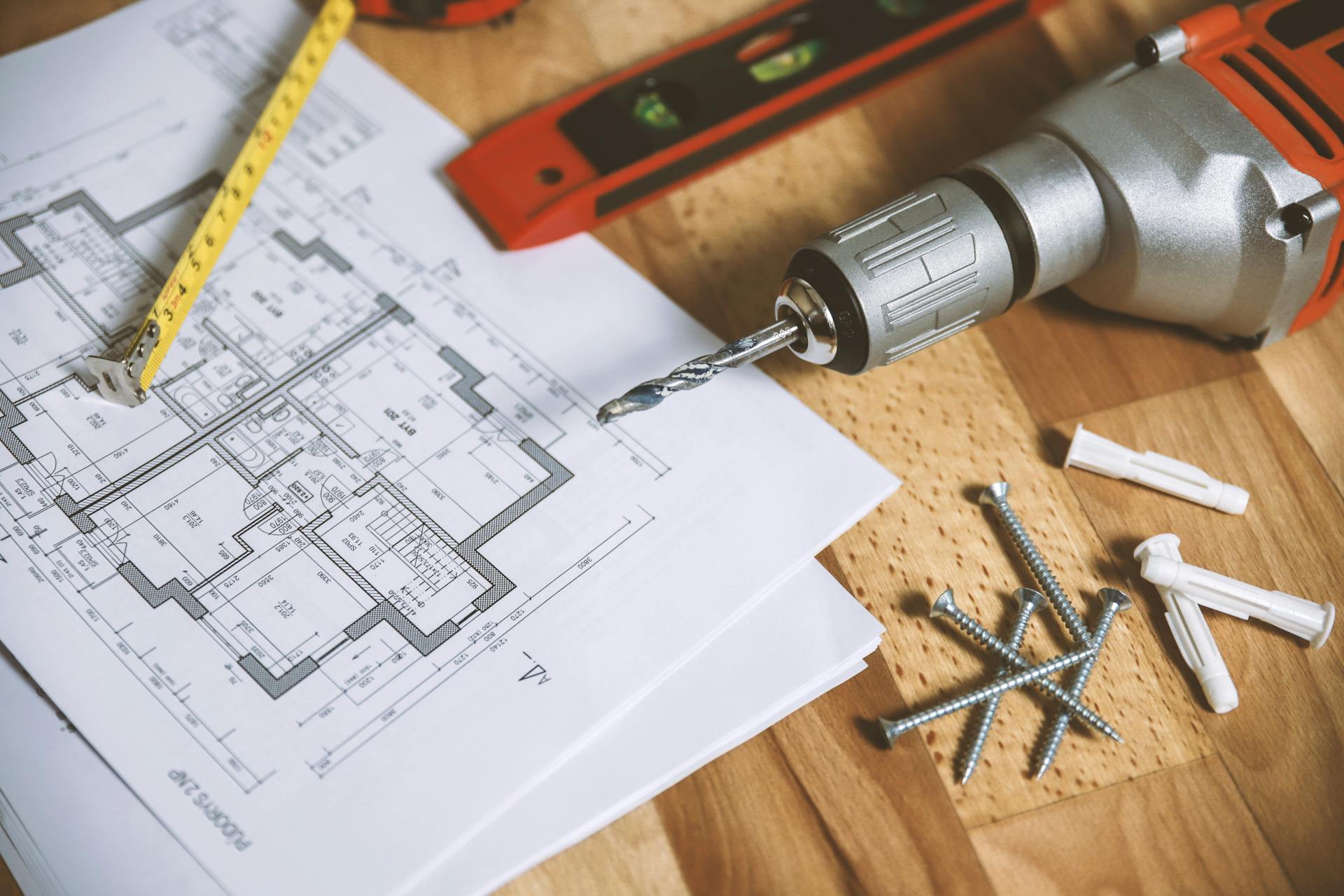

What equipment is needed for sublimation printing?

Sublimation printing is a process of transferring an image onto various materials, including fabric and metals. This type of printing provides a high-quality look and finish with vibrant colors. The main pieces of equipment needed for sublimation printing are heating presses, sublimation inks and paper, sublimation transfer films, as well as the appropriate printer.

Heat presses are what actually set the ink onto a substrate during the sublimation process. They range from industrial-sized presses used in commercial printing to smaller ones used by crafters and hobbyists. When selecting one, buyers should keep in mind the size of their projects and materials used in addition to budget.

Sublimation inks create vibrant colors requiring the use of special transfer paper that is fed into the printer. The inks should be chosen carefully depending on what type of substrate they will be printed on; fabrics typically require dye sub ink while metals require pigment ink. Lastly, nonstick sublimation transfer films are available and come in different sizes to fit different substrates being printed on such as mugs and t-shirts.

When all these components are combined with a quality printer model suited for sublimation printing, users can achieve professional-style results with improved reproduction quality. With proper care and maintenance, your setup should serve you well for years to come!

A unique perspective: What Is Azure Used for

How do I set up a sublimation transfer printing workflow?

Setting up a sublimation transfer printing workflow can be a daunting task, but with the right preparation and knowledge it doesn't have to be. Here are the steps you need to take in order to create a successful workflow.

The first step is to select the right equipment and materials. Sublimation printing is usually done using inkjet printers, a heat press, and transfer paper that has been specifically designed for sublimation. It's important to choose transfer paper with the correct image quality you want, as this will determine how well your design transfers from the paper to your target object or garment. Additionally, you need to make sure that the printer you are using can handle the type of transfer paper you choose—inkjet printers vary greatly in terms of which papers they can print on and some require specialized drivers or software packages.

Once you've collected all of your supplies, it's time for you to prepare for production. Depending on what material you are working with, there may be some surface preparation steps necessary before printing on them—such as adding PTFE sheeting or surface cleaning. It is also important that your imaging software is prepared correctly so that colors can render accurately onto the desired substrate.

After completing these preparations steps, you can begin aligning your image properly in the imaging software and start printing out your design onto transfer paper using an inkjet printer. From there, feed the printed design into a heat press machine at optimal heat conditions outlined by the specific material manufacturer specifications and then clamp down until desired pressure is achieved and all colors have transferred fully. That’s all it takes! With these steps correctly followed in an organized way, setting up an efficient sublimation transfer printing workflow should be fairly straightforward!

Worth a look: Printing Press Blankets

What substrates are suitable for sublimation printing?

Sublimation printing is a unique and versatile form of printing that uses heat to transfer dye onto various substrates, producing a vibrant, full-color result. While many substrates are suitable for sublimation printing, some materials are better than others in terms of durability and clarity of the printed image.

One good type of substrate for sublimation printing is polyester fabric. This fabric has excellent color retention capabilities and allows for seamless transitions on the print. Additionally, it does not lose its shape after stretching or exposing it to heat during the sublimation process. When using this material for sublimation printing, it is important to use higher temperatures due to the thicker fabric material.

Another ideal substrate is hard surfaces such as metal and ceramic plates. These materials can be pressed directly against to transfer ink without being harmed by the process. Ceramic tiles such as mugs and plates produce bright images with no visible pixels or rough edges. For aluminum surfaces, image clarity and color are important so these need special treatment prior to printing, like an etching primer coat which allows more vibrant colors while withstanding harsh conditions outdoors.

Finally, rigid plastic materials such as acrylic, PVC and ABS plastic offer great results when used with sublimation prints as they are more stable than other plastics which may get damaged when exposed intense heat during the process. Additionally, they tend to have very high resolution images due to their smooth surface making them perfect for signs and point-of-sale displays with clear results even at small sizes.

Therefore, when needing a durable product or high quality finish for signages or point-of sale items, many types of substrates can be used with great results in terms of clarity and color retention when using sublimation prints like polyester fabrics, hard surfaces like ceramic tiles or aluminum plus rigid plastics such as acrylics or ABS plastic among other options.

Curious to learn more? Check out: Melamine Plates

What is the best quality sublimation printer on the market?

The best quality sublimation printers on the market today are those that combine speed, cost-savings and flexible printing capabilities. It is important for consumers to choose a sublimation printer appropriate to the scale of their projects, as well as individual budget requirements.

For high-volume printing needs, the best option is typically a commercial-grade digital dye-sublimation printer. These powerful machines deliver fast production speeds and crystal clear prints with unmatched sharpness and detail. They are capable of producing several thousand prints per hour, with media sizes of up to 18 inches wide and 24 inches deep. In addition to being an efficient output solution for large volume tasks, many commercial models include automatic inksaving devices for added cost savings over time.

For smaller projects or those with limited budgets, desktop dye-sublimation thermal printers provide excellent performance at a more reasonable price point. These machines usually have slightly slower output speeds compared to commercial printers due to their smaller size but they have media printing capabilities up to 8 inches wide and prodcue high resolution prints as well. As with most technology, newer models tend to offer higher production speeds along with improved image quality than pre-existing models, so this should be taken into consideration when choosing the right sublimation printer for individual applications.

When selecting a sublimation printer it is important to consider both immediate needs and future goals in order to achieve the best results from your investment. Whether you are looking for the top-of-the-line commercial grade digital dye-sublimator machine or a more affordable option for smaller projects, there is a perfect sublimation printer on the market today—ready to bring your ideas into reality!

A unique perspective: Commercial Printing

What type of inks are used in sublimation printing?

Sublimation ink is an essential component for any sublimation printing process. Sublimation printing is a unique digital print technology that uses heat to transfer dye into the fabric or other substrate to create stunning designs and graphics. Sublimation ink provides superior vibrancy and crisp detail, making it perfect for a wide range of applications.

Sublimation inks come in a variety of types, with the most common type being disperse dye inks. Disperse dyes are small-particle colored solids that become liquid when heated and solidify when cooled, forming a permanent bond with the substrate material. The particles embedded in the fabric retain their original color over time - providing bright and vibrant prints with excellent durability.

Another popular type of ink used in sublimation printing is reactive dyes. Reactive dyes form an intense bond with the fiber which results in permanently printed, full-color images that are less likely to fade or discolor over time. Additionally, reactive dyes offer superior wash-fastness and tend to cost less than other type of inks used in sublimation printing processes.

Finally, acid dye makes up another type of ink used for this unique printing method. Acid dyeing is capable of producing vibrant and eye-catching prints as well as offering considerable durability on cotton fabric and other natural fibers such as wool or silk.

Overall, there are several different types of specialized ink used for sublimation printing processes. Disperse dyeinks are popular because they offer great color permanence while reactive and acid dyes provide vivid colors as well as high levels of washability - allowing you to print beautiful images that will last a long time!

Curious to learn more? Check out: Foil Print Fabric

Sources

- https://contentmavericks.com/best-sublimation-software/

- https://silverbobbin.com/best-sublimation-printing-software/

- https://fixthephoto.com/best-sublimation-design-software.html

- https://sublimationhome.com/best-sublimation-software/

- https://leapoffaithcrafting.com/sublimation-printing-for-beginners/

- https://subliprinting.com/software-for-sublimation/

- https://podi.org/sublimation-software/

- https://subliprinting.com/how-to-do-sublimation-printing/

- https://printartisty.com/best-software-for-sublimation-printing/

- https://www.makesecured.com/equipment-needed-for-sublimation-printing/

- https://ecombridges.com/best-software-for-sublimation-printing

- https://www.paperflodesigns.com/blog/software-for-sublimation-printing/

- https://hodino.com/sublimation-design-software/

- https://www.3dsourced.com/3d-software/best-sublimation-software/

- https://leansublimation.com/product-reviews/best-sublimation-softwares-for-design-in-2021-ranked/

Featured Images: pexels.com